Plug & Play brings every Veev home together in record time

Our proprietary Plug & Play system connects our wall panels in seconds, eliminating delays and rising building costs

May 13, 2023

The home-building industry’s ongoing shortage of skilled labor is a roadblock that has a ripple effect impacting nearly every new build. Declining trade workers are leading to delayed project timelines (often spanning many months), and with demand for labor outweighing supply, wage rates are going up along with total costs. All of this contributes to America’s housing crisis — the U.S. is short upwards of 5.5 million homes — with the problem only becoming worse.

At Veev, we saw this growing challenge as an opportunity to innovate. We wondered: What if we could build a smarter and higher-quality home in a fraction of the time? What if we could bring the build process in-house and up to modern standards, instead of relying on outdated practices and a shrinking workforce?

These questions inspired every aspect of our vertically integrated build process. They’re what led us to develop our proprietary Plug & Play methodology, a connector system that joins one wall panel — already outfitted with all mechanical, electrical, plumbing and fire protection (MEPF) — to another in a matter of seconds, nearly as easily as your phone charger plugs into a wall.

Plug & Play is the final step of our efficient build approach. It allows us to take the original questions that fueled Veev’s founding into a reality: building better homes more efficiently.

The current reality of home building

We invented the Plug & Play system as part of our broader mission to move away from building a home entirely onsite, where fragmented processes require specialized labor that cause costly delays and problems.

MEP construction

Think of everything that goes into a traditional build onsite: After the foundation is laid and the framing is constructed, MEPF elements need to be fitted. That means coordinating between the schedules of a plumber, electrician and other subcontractors who are booked out for weeks or months, while ensuring inspection regulations are met at each stage.

Each element of MEPF is a potential bottleneck that could cost thousands of dollars.

Due to both labor and supply challenges, a home build today that should take one year to complete is now stretching past 16 months, with each month meaning more dollars spent. Contract work accounts for up to 90% of the total cost on a construction project, which can result in large fluctuations in a project budget. The unpredictability of the current process simply isn’t sustainable.

How Plug & Play works — and saves time

Our Plug & Play system allows us to reduce our dependence on hard-to-come-by contractors and take build timelines into our own hands.

The technology itself is responsible for unifying all MEPF components of one wall panel, which are then joined together via a connector system. It is the final step of our vertically integrated approach to building a single-family home — a process that begins with a digital design.

Advanced digital integration

Using a digital twin software, our team routes all MEPF components of a home within a digital model. This means, before the walls are even built, we know where electrical needs to go, where pipes need to connect and where heating and air systems will be housed. The system is standardized as much as possible across our digital system and production lines to make the design process easily repeatable and fast.

The Closed Wall system

Using the information from the digital twin, we send build and design specifications for each wall panel directly to the assembly line of our Digital Fabrication Facility to complete our Closed Wall system, a five-step process that includes building the steel frame, applying foam insulation and applying High Performance Surface (HPS) to close one side.

From there, the wall is fitted with necessary MEPF components following the digital design. Once that step is complete, we close the wall with HPS on the other side.

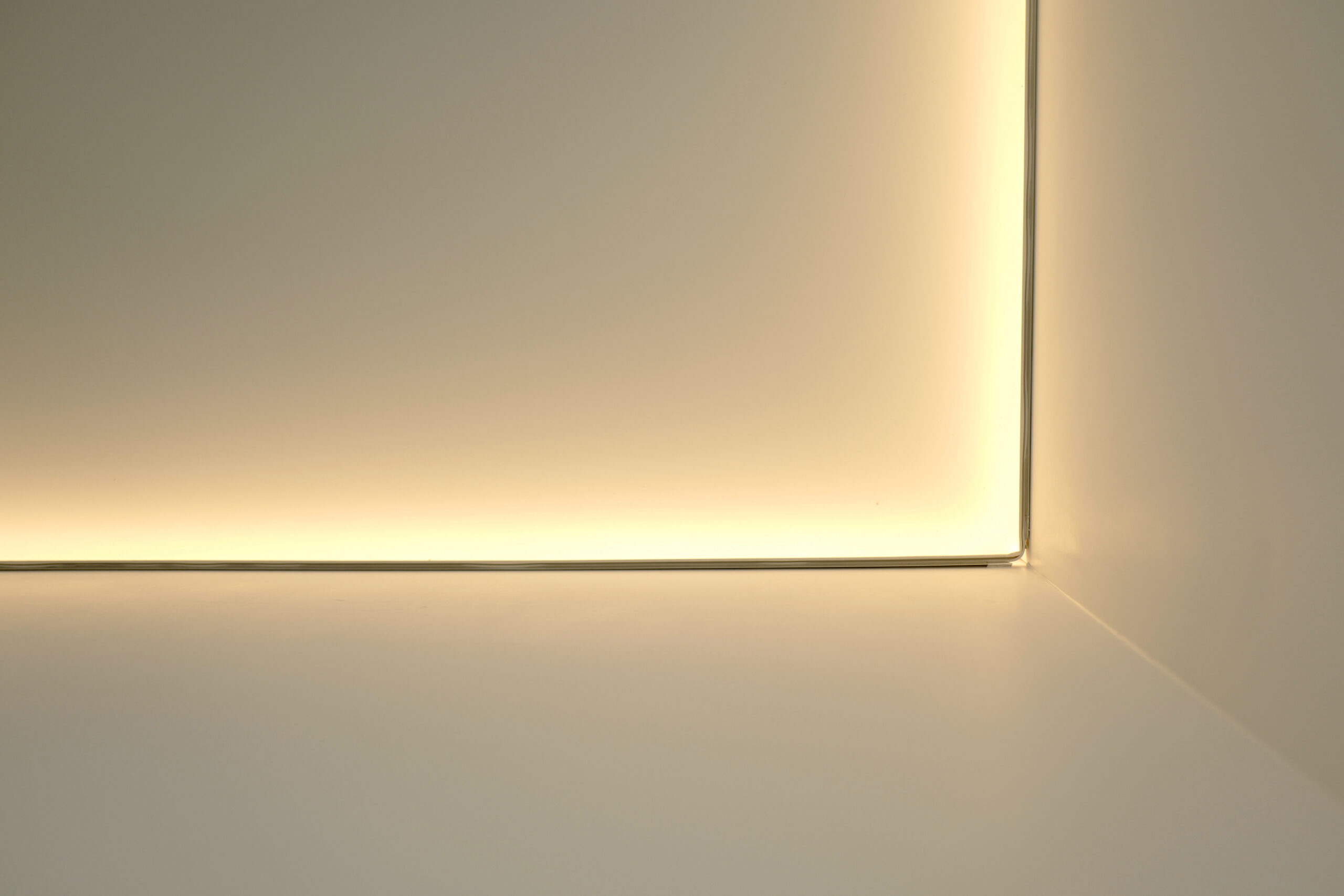

One master plug simplifying all cables at the top corner of each wall makes it easy to connect walls onsite in a matter of seconds.

After each wall panel is connected, plugs are hidden under our stretch ceiling system for a clean, finished look.

There’s a reason it’s called Plug & Play

Once the walls are transported to the build site, a Veev team member — with no specialized trade licensing required — simply connects the connector system, joining each wall via a traditional plug and socket. The process, similar to plugging in any other piece of technology you use today to charge, takes only a few seconds.

On average, a 2,000-square-foot single-family home can be fully connected and functional in as little as two days

with the help of four Veev crew members.

A new way to build homes

We set out to completely reimagine every step of home-building to solve for the industry’s current challenges and work toward a more modern and efficient way to build homes. Plug & Play is a critical component of this streamlined build process. It enables us to industrialize home building to produce superior quality homes in less time and for less money.

Plug & Play is just one way we’re revolutionizing the entire home-building experience and building homes that are better for the planet. Read more about our streamlined build process and approach to sustainability.