Premium windows, built in-house

What sets our European-style windows apart — and how crafting them ourselves speeds up build timelines

November 7, 2023

Supply chain issues hit the home-building industry hard in recent years, leaving builders scrambling to obtain crucial project components. Among them, windows emerged as an enormous source of stress for developers across the country.

At the height of the pandemic, wait times for windows surged from a couple of weeks to more than six months, leading to unprecedented project delays.

Surveyed home builders reported that windows accounted for more than 60% of all project delays in 2021.

Costs subsequently rose more than 30%, and incorrect orders only compounded the issue.

At Veev, this supply chain disaster accelerated the decision to bring window production in-house. Windows are just one of many home components we build in our digital fabrication facility, including our closed wall panels, doors, backsplashes, counters and other features. Bringing production in-house eliminates delays caused by external vendors, and importantly, gives our team control over the quality, efficiency and sustainability of our homes.

Over the past two years, Veev Window Product & Operations Manager Jesus Medina and his team have developed a premium-quality, European-style window unlike anything else available in the U.S. We recently sat down with Jesus to learn more about the development of Veev windows, their unique features and how they play a critical role in our ability to produce a single-family home up to six times faster than a traditional build.

Veev hired you in the middle of the pandemic to build a window product from scratch. That’s no small feat. How did you get started?

Windows are what I know. I’ve worked with them ever since my first job out of high school, and my previous positions involved building window products for different companies.

I came to Veev when the lead times for windows were ridiculous. But that wasn’t the only factor behind the decision to build in-house. The reality is that when you purchase windows, you’re locked into the manufacturer’s window system, which limits your design.

We wanted to build a window that integrated perfectly into the Veev ecosystem for ultimate control of our product.

To get started, I first had to determine which materials would be best suited for homeowners while aligning with our build process and sustainability objectives. Then, I focused on acquiring the necessary equipment and constructing the production line.

Veev uses aluminum for its windows instead of vinyl. Why is this the better choice?

Vinyl windows are more commonly found in homes throughout the U.S., while you typically see aluminum windows in high-end properties. Vinyl, being plastic, tends to create a thicker profile and be more susceptible to damage. Aluminum windows are significantly stronger and structurally safe, with less risk of bowing or warping due to weather or natural disasters.

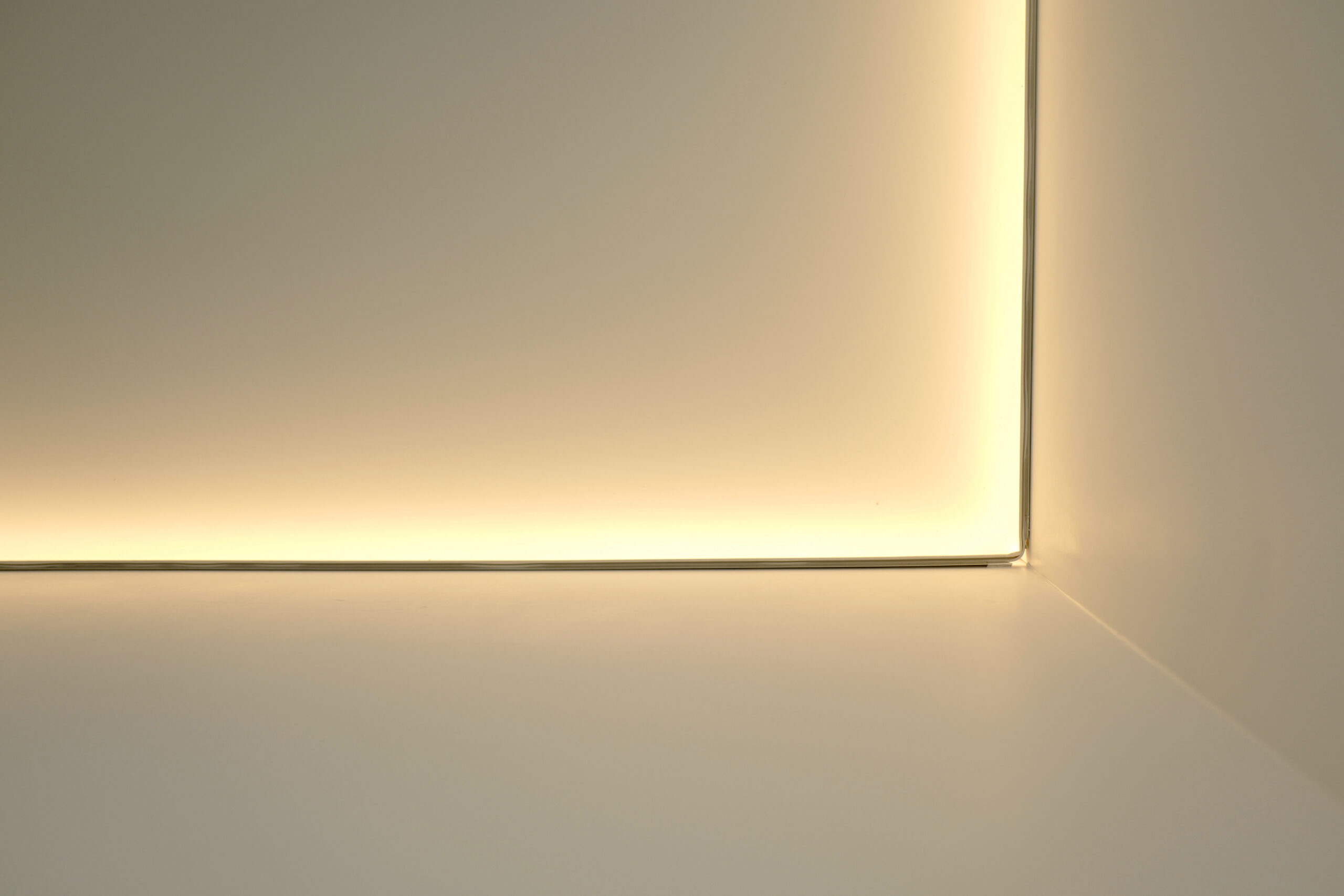

Aluminum’s strength means our window profile can be thinner—as slim as an inch—providing clean sightlines and nearly unobstructed views. Aluminum is also much more recyclable than vinyl.

States such as California are becoming more strict about thermal requirements. How does aluminum measure up in terms of thermal properties?

Aluminum can easily transfer heat or cold from outside your home to the interior. That’s why we choose to thermally break our aluminum window framing. We take two pieces of aluminum and sandwich a layer of Polyamide between them to create a window profile that provides much better insulation. We also insert what we call an “energy bar” made of foam insulation to give our windows even better thermal properties.

The style of Veev windows also differs from others on the market. How so?

The beauty of creating a window from scratch is that we didn’t have to go with the status quo.

In the U.S., sliding or double-hung windows are the norm. In Europe, tilt-turn windows have become the standard, which can better seal air-tight. Our windows adopt this European style, with a handle that lets you turn it inward from a vertical hinge and tilt it inward from a horizontal hinge to vent the window without opening it fully.

This style also can handle larger glass surfaces with less bulky framing. That creates a cleaner look.

Are there any other benefits of Veev windows?

While not a part of the window itself, we also place embedded sensors on every window that will notify you if it’s open or locked, as well as custom and programmable shades. The Veev Digital Home controls both of these features. Homeowners can control the shades and lock windows through the Veev app or in-home wall panels.

How do the windows fit into the closed wall system and help power Veev’s efficient build process?

Our windows are made in the same Digital Fabrication Facility as our closed wall panels. Our window software optimizes aluminum cuts to be extremely precise and minimize waste. Once a window is framed, equipped with hardware and sealed, it’s ready to be installed in the wall.

Every detailed measurement of a window feeds into the Veev digital twin software that’s powering the home build. They become perfectly translated into the overall home design. It’s kind of amazing how precise the windows are thanks to this system.

Windows are placed in the closed wall at the very end of our production line, right before the last step of weatherproofing and being delivered to the build site. All of our windows are NFRC certified, as well as WDMA certified for structural performance, air infiltration and water resistance.

What’s next for window production at Veev?

Our long-term vision is to have an almost fully automated window line. Imagine a nearly 20 feet aluminum extrusion entering an assembly line and coming out a fully formed window.

Since we own the window and the full wall, we can change whatever we want and go beyond what is traditional. The possibilities are endless.

To learn more about how we’re reimagining home building, read all about our ultra-efficient build process.